Several months ago, I redid the storage setup for my wife. We pulled out the old setup, and installed a corner cabinet for shelf storage, which helped solve that pesky “what do you do with a corner of the closet” problem. It was a fun little project, and it helped to save money vs. having some professional company come in the redo the closet. One of the issues she has, however, is that the top shelf is difficult to reach, so she needed some sort of stool or bench in order to get to the top level. If possible, she’d like it to be able to slide under the closet cabinetry, which is suspended 13 inches off the floor (and attached to the wall).

I happened to know have an article in one of my woodworking magazines with a Shaker-style stool, and it is built entirely by hand tools. It has tenons on the legs which go through the top, and four angled “struts” which are dovetailed into the sides to provide further strength. Gives me the opportunity to practice my hand tool skills. The first step was cutting everything to size.

Next, I had to saw and cut the legs tenons and the arched foot. I used my carcass saw for the straight cut down, and then a coping saw to take out the waste. Was pretty successful in getting that out, and only had to do a little cleanup with a chisel

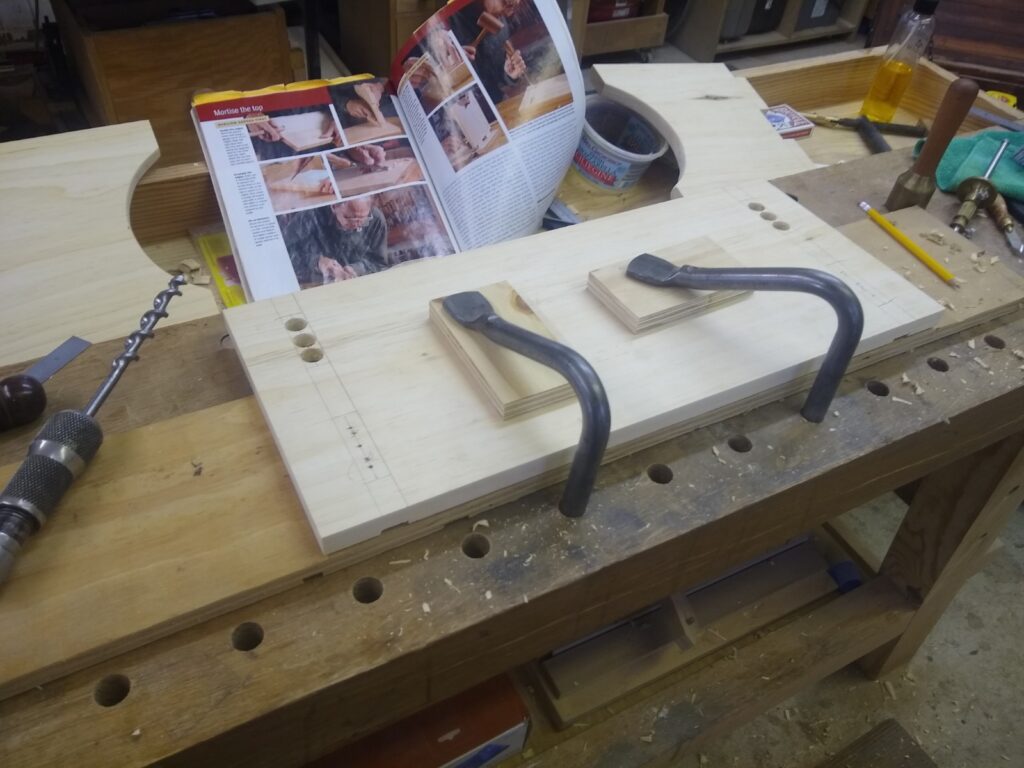

From there, I clamped the stool top down to the workbench, laid out the dados, and then sawed them out to 1/8” deep. From there, I used a chisel, bevel side down, to clean out the waste, and a router plane to get it to final depth

After that, I drilled out holes through the stool top for the “tenons” of the legs, which will go through all the way to the top (i.e. through tenons). I had cut the tenons 1/8” long, so they would stand “proud” of the stool top.

I then cut 45-degree angles in the 4 “struts” that help support the top. They were cut so they would stand proud about 1/16” at top and get. With those, I was able to mark out the angled pieces in the top and the legs. I sued my carcass saw to make the cut, used the coping saw to clear the majority of the work out, and then my chisels to clean it up to the measurements

Once that was done, I glued and clamped it all up. Once secure, I used a chiseled the clean up the tenons standing proud, and then sanded it down to 220Grit. From there, a couple of coats of shellac and then its ready to go.

Its now sitting in my wife’s closet, ready to go.

Kevin