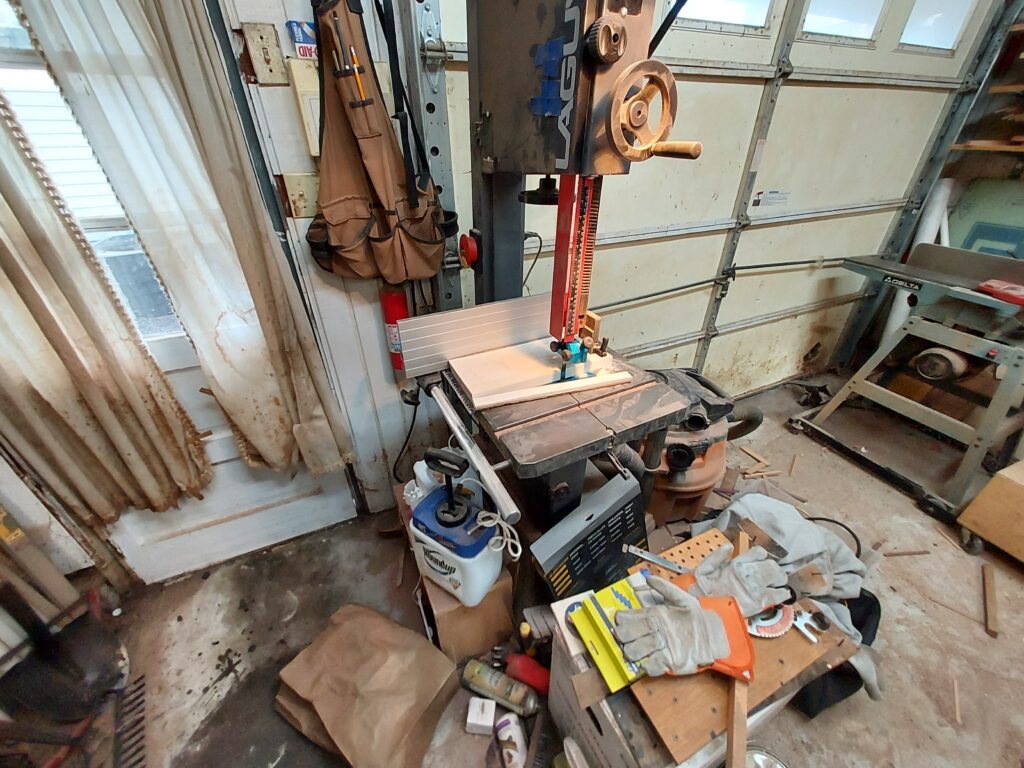

My niece Christina wanted a live edge floating shelf, so for Christmas, I decided to make her one. I had to bandsaw one end to clean it up and then ran it across the jointer to make sure the one end was flat and square.

From there, I had to lay out and drill the holes for the two 5” long “pins” that go into the shelf to support it. Did not have much wiggle room either way, so had to make sure it was straight and true.

From there, I laid out the mortises for the pins, as they had two rectangular “flanges” that had to sit about ¼” deep into the shelf, so I used a knife to outline them on the back of the shelf, and then a chisel and small router plane to clean out the mortises.

I had earlier purchased a maple live edge, but she decided she wanted a darker color, so I had to stain it with a Walnut stain. After that, I put on three coats of shellac to seal the wood. From there, I sanded to 320 grit sandpaper.

With that done, I organized the hardware, which was two black “pins” and four sets of drywall hangers/screws, which allows them to be either screwed into a stud or into drywall. The supports will hold a shelf up to 50 lbs.

Overall, not a difficult project, the biggest issue is cutting the mortises in the back.

Merry Christmas!

Kevin