I was sidelined for about 2 weeks due to a back/hip injury (sciatica). Makes it difficult to bend over, lift and manipulate items, plane wood, etc. So my spouse made we relax, stretch, and do mild exercise – and stay out of the shop. Very agonizing….

Well, feeling better now (not 100%) so its time to get to work. The last farmers’ market cleared me out of end-grain cutting boards and small picture frames, so its time to build some more. In addition, I’ve got Christmas gifts to build for the family, so I have to work on that. Only 4 weeks till the final farmer’s market of the year, so I need to build up inventory for folks trying to buy stuff for the holidays.

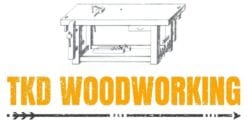

The first step in building and end grain cutting board is to cut a quantity of strips of various woods to size.

Then you glue those up with waterproof glue and let them sit overnight to harden

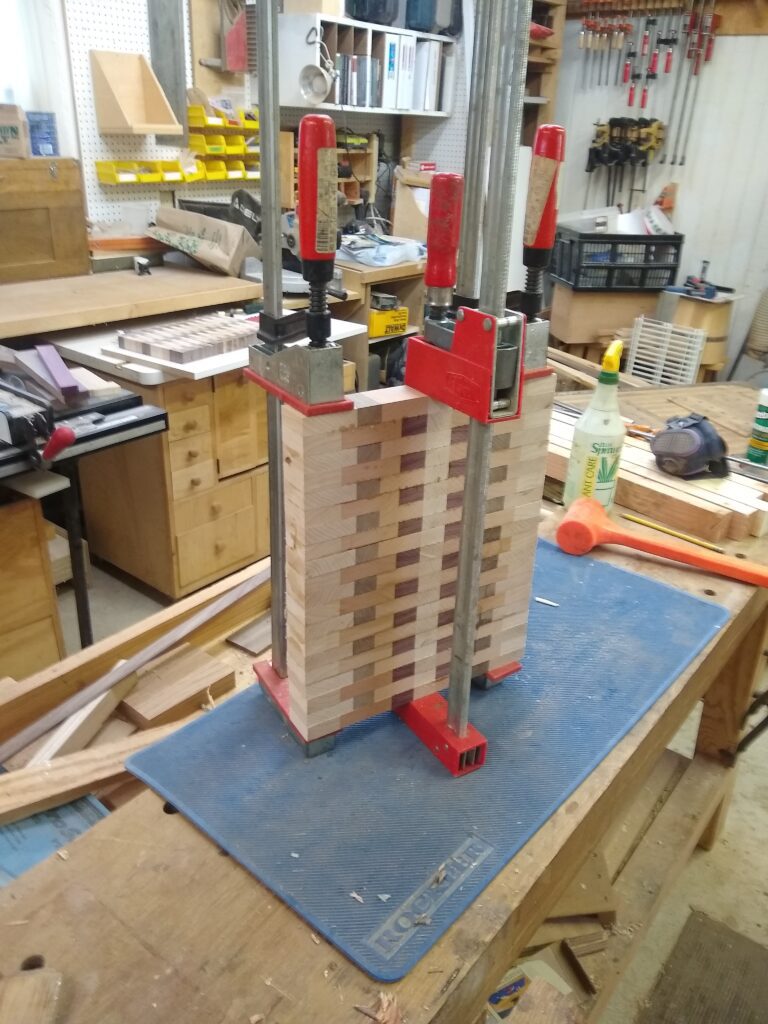

After that, you need to plane them down so that its all level, and then cut them again into new strips the depth of the cutting board (in this case 1 -1/4”)

From there, its regluing them up in groups (so they don’t get out of alignment trying to glue too many strips at once) and then gluing up the mass

From there, its on to final planning and sanding, rounding over the edges, and putting the feet on the bottom after applying a couple of coats of cutting board oil on

Whole process takes several days, primarily due to needing the glue to dry completely before moving on to the next step.

Kevin